.webp)

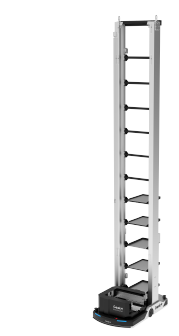

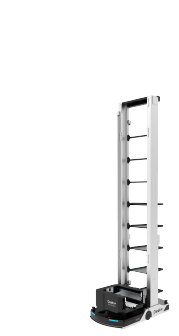

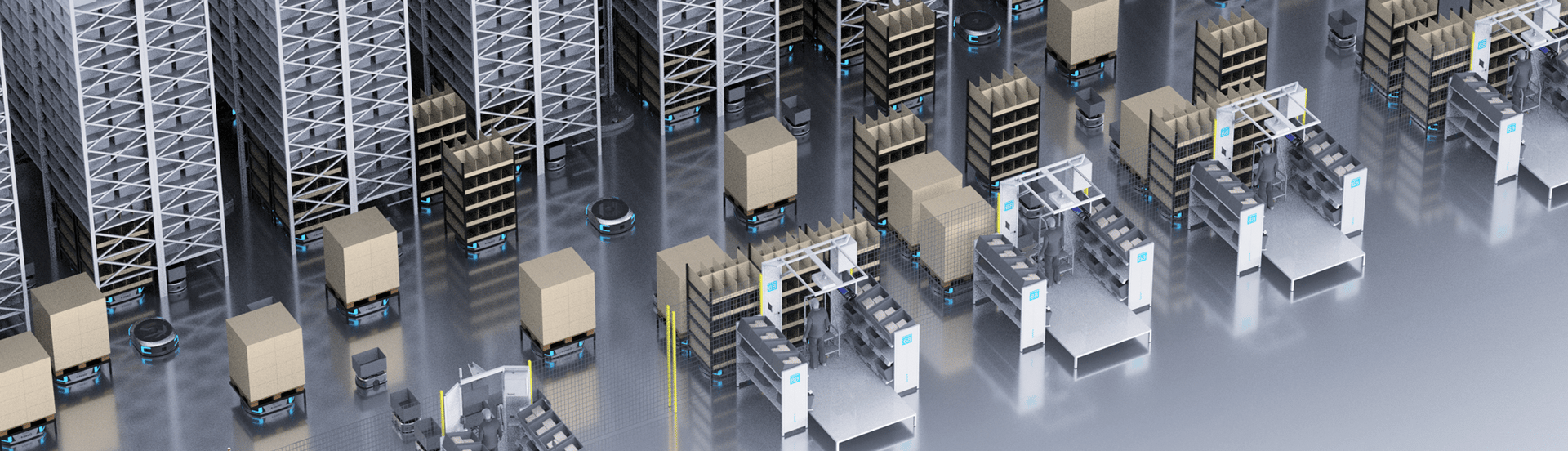

The Tote-to-Person solution handles vertical storage and fast retrieval of totes, while the Shelf-to-Person solution brings shelves and large items to picking stations.

Applicable industries:

The Geekplus Tote-to-Person system was certified as "Best of Intralogistics 2020" by the world-renowned IFOY award, one of the industry's most prestigious recognitions. Compared with the traditional warehouse shuttle system, RoboShuttle has higher flexibility, efficiency and return-on-investment.

The Tote-to-Person solution handles vertical storage and fast retrieval of totes, while the Shelf-to-Person solution brings shelves and large items to picking stations.

Applicable industries:

-Picking and storing scenarios of varied sizes

-Whole carton/pallet and piece picking and storing scenario

-Mixed popularity picking and storing scenario

-Applicable industry: E-commerce, apparel, retails, pharmaceuticals