A professional software system deeply adapted to the industry with full coverage of diversified

systems. These robust systems make it easy for customers to use and integrate.

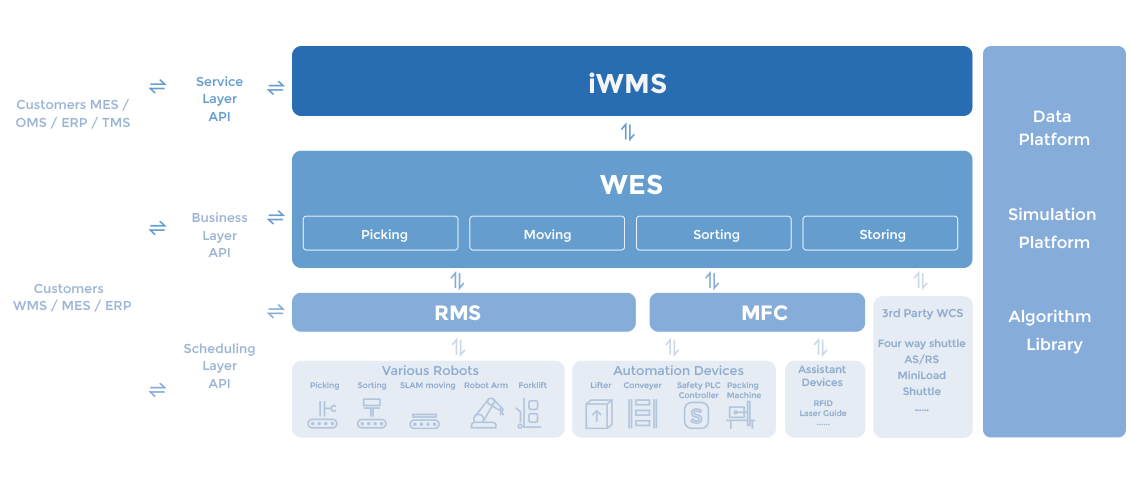

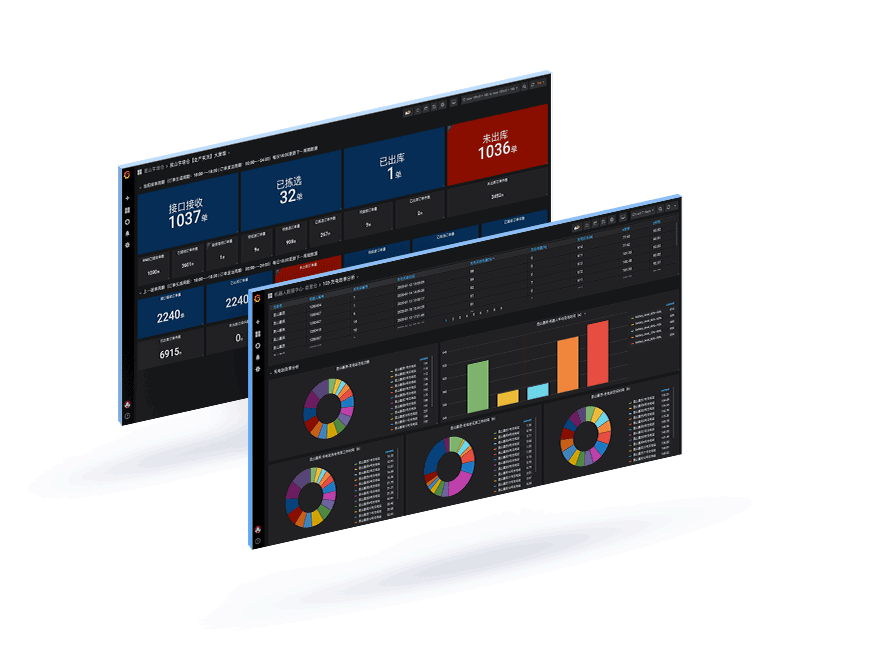

Geek+ provides customers with a professional software system deeply adapted to the industry with full coverage of Robot Management System, Warehouse Execution System, Warehouse Management System, Data Platform, simulation platform, algorithm library, and highly modular and flexible interface platform API and SDK. These robust systems make it easy for customers to use and integrate.

Geek+ Robot Management System (RMS) is a multi-agent scheduling and task management platform system. It supports both cloud and local deployment, simultaneously prepossessing path planning, traffic management, task allocation, capacity optimization, safety emergency stops, and other tasks of large-scale mobile robot cluster, in real-time with high concurrency and reliability. Geek+ RMS provides APIs and SDKs with open standards making it easier for customers to develop and deploy business systems.

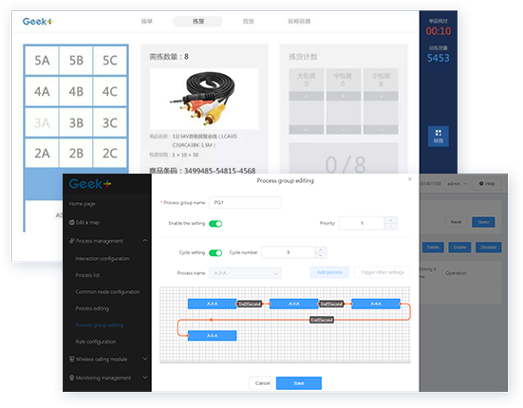

Geek+ Warehouse Execution System (WES) covers all operational links of warehouses and factories, including four subsystems: picking system, ARK moving system, sorting system, and forklift system.

The picking system supports shelf-to-people system, and bin-to-people picking, suitable for many industries. It has flexible configurations, able to receive the picking tasks from the customer iWMS, optimize and combine the items, and perform efficiently. The flexible ARK moving system deals with multiple moving scenarios such as loading and unloading goods, storage on the dock, and factory production line feeding, etc.

The sorting system can dynamically adjust the route, improve the sorting efficiency, suitable for parcel sorting, store distribution sorting, and cross-warehouse sorting. The forklift system is applied to the whole-pallet storage and high-level storage of the warehouse, and realizes the loading and unloading of whole-pallet goods in combination with the AGV.

Each module has the flexibility to combine processes to form a variety of composite systems. At the same time, the system integrates into the equipment process control system MFC and the partner's control system to form a complete smart execution system.

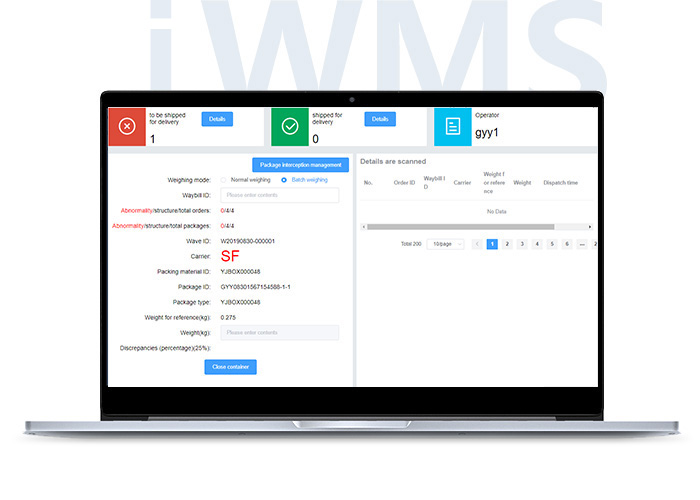

Based on the Geek+ Robot Management System and the Geek+ Warehouse Execution System, Geek+ Warehouse Management System (iWMS) effectively integrates all links of warehouse operation with robot picking, sorting, cross-warehousing, handling, access, and manual management, providing a complete solution for warehousing operations, and helps to meet the high market demand for speed and flexibility.

Geek+ iWMS has been tested by several large e-commerce sales such as the Singles Day sales in China, proven the capability to process orders at 30 times the amount processed on an average day. During the Singles Day sales in 2019, the system processed 8.11 million orders delivery.

Geek+ Data Platform (DP) provides date support for highly efficient robotics solutions. It stores the mass data generated by RMS, WES, iWMS, and by the robot itself in the data lake after calculation by the data flow processing platform in real-time. The data lake provides data support for visual reports, simulation, business intelligence (BI) analysis along with smart robots maintenance.

Geek+ Simulation Platform (SP) is a 1:1 simulation of real robot systems designed to help find the best plan and configuration before a project begins, validate the plan effectiveness and the algorithm, and further support on project evaluation and management, eventually creating reasonable ROI.

The Geek+ SP integrates the planning tools, map editing tools, simulation tools, robot models, and other modules. Geek+ SP then digitizes all of the attributes of the storage and production scenarios, and integrates the algorithm library.